Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

The bolt-ball space frame is a large-span steel structure commonly used in large construction projects. Utilizing this space frame for large-span construction effectively shortens construction time, simplifies the process, and reduces on-site welding, with small welding errors that are easily adjustable. However, in recent years, with the widespread use of bolt-ball space frame structures in buildings, incidents of structural collapse have occurred. Therefore, controlling the quality of bolt-ball space frames plays a crucial role in enhancing the stability and safety of their use.

1. Excessive deflection and surface paint peeling and corrosion during the use of the space frame:

After installation, the space frame may experience additional deflection when subjected to additional loads, even exceeding 1.15 times the design value specified by the standard, posing serious safety hazards. Severe paint peeling and corrosion on the surface occur around 5-10 years after installation, affecting aesthetics and threatening the structural integrity of the space frame.

2. Deflection and axial misalignment during space frame installation:

Issues such as loose connections and gaps between high-strength bolts and ball joints, failure to tighten properly, and overall deflection exceeding 1.15 times the design value specified by the standard can reduce the overall strength and stiffness of the space frame, compromising safety.

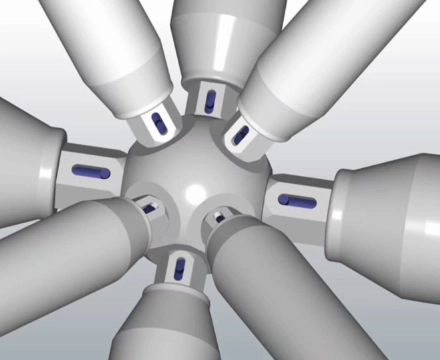

3. Excessive processing deviations in bolt-balls:

Significant deviations in the diameter, roundness, unbalanced milling surfaces, and threads of bolt-balls can lead to installation beyond permissible tolerances. This affects the space frame’s dimensional requirements and axis alignment, impacting its load-bearing capacity and posing safety hazards.

4. Insufficient bolt length in high-strength bolts inserted into bolt-balls:

During construction, the threaded length of high-strength bolts inserted into bolt-balls is hidden, making measurement and assessment challenging. Insufficient bolt length can pose safety risks, directly affecting the strength and stiffness of space frame node connections.

5. Deviations in member processing dimensions and perpendicularity of cross-sections:

Quality issues, such as deviations in the length of space frame members, perpendicularity of cross-sections to the pipe axis, and misalignment of pipe mouth axes, beyond the permissible limits specified by standards can make assembly and installation challenging. This results in significant geometric dimension and member axis deviations, non-compliance with design requirements, and a reduction in structural load-bearing capacity.

6. Insufficient strength in high-strength bolts:

The tensile strength of high-strength bolts in bolt-ball node space frame structures is a major factor affecting node load-bearing capacity. The strength is related to surface hardness, so quality assurance of high-strength bolts can be achieved through hardness control and surface hardness testing.

Steel space frame structures, a new structural form widely promoted in the past two decades, consist of bolt-ball nodes and steel pipe members connected by high-strength bolts or welds. They offer advantages such as low steel usage and ease of construction. With the rapid development of China’s socio-economic conditions, an increasing number of steel space frame structures have been applied in large-span projects, including sports stadiums, airport waiting halls, train station waiting halls, gas station canopies, industrial plants, and large storage warehouses.