Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

This is where the magic happens. We take the approved plans of the space frame design modeled in our engineering software and transfer them into SAFS’s proprietary software. This technology assigns length and sizes to all members and generates the program for the CNC node-drilling machine, ensuring accuracy. All components are then manufactured in SAFS’ factory using domestic GB standard materials. Each member is cut exactly to specifications automatically and then stamped with a number that coordinates with the construction plan.

Once all items are fabricated, the pieces are laid out to create the desired shape within our facility. At this point, parts are hot-dip galvanized, powder-coated or colored…based on the approved design that meets the aesthetic vision set forth by the architect…for an industry-best corrosion-resistant finish.

Finally, balls, sleeves, and pins are assembled by hand so that the space frame structure is ready to be assembled when it arrives on site. To prepare for shipping, all members are stacked and wrapped in special export material, and the packages are ready to be transported to their destination anywhere in the world.

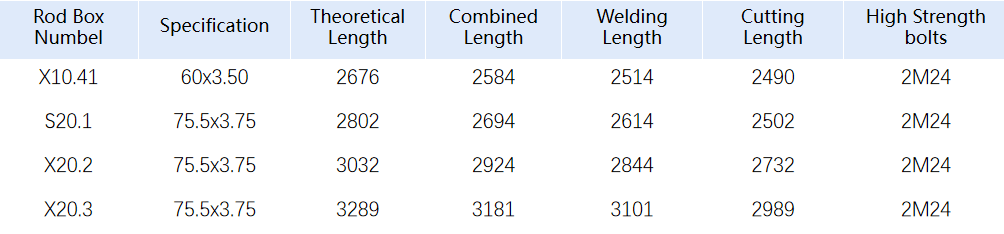

1. Steel Pipe (According to the final design and shop drawings, welding pipe blanking + sealing plate / cone head for welding.)

Welded Pipe Arrived The Factory

Measuring Thickness

Blanking

Combination Spot Welding

Pipes sandblasting and derusting to SA2.5 Grade

UT inspection

Auto Welding

Inspection Size

Primer Paint

Surface Paint

After painting, the pipes measure whether the thickness of the dry film reaches the standard ( Total 3 layers, NDFT not less than 150μm)

Finished Pipe Packaging

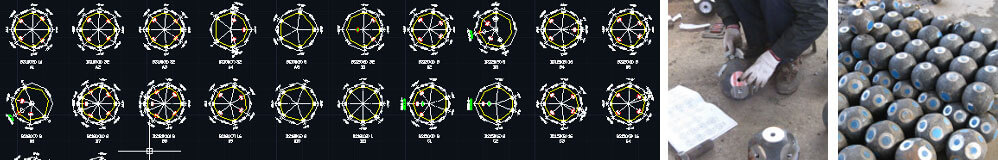

2. Space Frame Components - Bolt ball, Cone, high strength bolt, blanking plate, sleeve,

Bolt Balls

Each project is based on the final design and shop drawings, the size and aperture of each bolt ball are different, and it requires professional workers to use special machines for processing.

3. Packing & Delivery

Quality Control System

SGS

BV

CNAS

National space frame and steel structures quality supervision and inspection center

Laboratory Testing