Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

Welded ball joints are a common connection type in space frame structures, where hollow steel balls link the members. The ends of the members are rigidly connected to the balls through on-site welding, forming a rigid joint.

Its core characteristics include clear force transmission and high connection stiffness, resulting in excellent structural integrity and stability for the space frame.

It can flexibly connect members of varying orientations and quantities, accommodating complex grid layouts with strong design adaptability. However, it demands extremely high standards for welding quality and precision.

Primarily applied in medium-to-large span spatial structures requiring high rigidity and load-bearing capacity, such as roof systems for large public buildings including stadiums, exhibition centers, railway stations, and industrial plants.

The welded ball is hollow—this is crucial. Understanding this concept will help you grasp the subsequent manufacturing process.

Let’s cut it open and take a look. It looks like this.

The sphere incorporates rib plates to enhance its rigidity and strength. Unlike bolted spherical nodes, welded spherical nodes are typically used in large public buildings such as stadiums and stations. These structures feature extensive roof spans and large areas, necessitating the transmission of substantial loads. Consequently, the node volume cannot be small. However, if all nodes were solid, the cost would inevitably increase significantly. Moreover, installing such a heavy solid sphere would pose considerably greater challenges.

Engineers thus devised the “hollow + stiffener plate” configuration (PS: Stiffener plates may be omitted for smaller spheres). This approach maintains the sphere’s strength and rigidity while reducing material costs and weight, achieving structural harmony.

So how is it made?

| 1 | Cutting and blanking of hemispherical steel plates. |  |

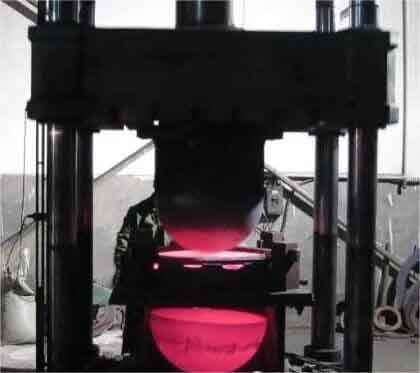

| 2 | Steel plates are pressed into spheres. |  |

| 3 |

Enter the heating furnace for heating. Hemispherical hot pressing molding employs a hot pressing process, requiring compression within specialized press molding machinery. |

|

| 4 |

Cut the bevel. After cooling, cut a hemispherical bevel to the specified dimensions using a dedicated lathe or specialized beveling equipment. |

|

| 5 |

Install stiffening ribs 1.Weld internal stiffening plates to the spherical body. For certain large-diameter spheres, internal partitions must be added. Set up dedicated assembly jigs. Mount the spherical stiffening plates onto the steel sphere assembly jig. After positioning and installation, secure them with spot welding. 2.Assemble steel balls and conduct inspections. Grind the bevels of approved hemispheres clean to expose the metal surface, then assemble the intermediate partition. |

|

| 6 |

The steel balls undergo gas shielded welding for the root pass, followed by submerged arc welding using a specialized ball welding machine. Upon passing inspection, they undergo ultrasonic testing. |

|

| 7 |

Rust removal and painting Once fabrication is complete, the components can be transported to the site for installation. |

|