Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

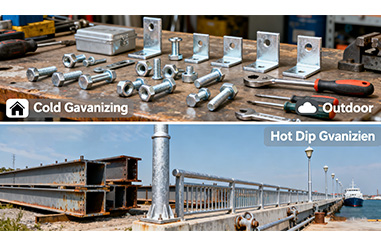

In industrial plants, logistics parks, large stadiums, and other structures, steel frameworks serve as the undisputed “skeleton.” However, steel is vulnerable to rust. Once corroded, its load-bearing capacity and service life are significantly compromised. Therefore, we must equip it with a reliable protective layer—a zinc coating—before it leaves the factory. The primary methods for applying this protective layer are cold galvanizing and hot-dip galvanizing.

I.Core Distinction: A Contest Between “Physical Wearability” and “Metallurgical Integration”

To understand the choice between the two, one must first grasp their fundamental differences.

Process: Thoroughly cleaned (pickled) steel components are immersed in molten zinc at approximately 450°C. This triggers a vigorous metallurgical reaction between the steel and liquid zinc, forming a zinc-iron alloy layer on the steel surface, topped by a pure zinc coating.

Coating Characteristics:

Exceptional Adhesion: The alloy layer integrates the coating with the steel substrate, creating a highly bonded, non-peeling finish.

Thick Coating: Typically exceeding 60μm, sometimes surpassing 100μm, offering corrosion protection lasting 20-50 years.

Appearance: Bright silver surface with zinc flowers, exhibiting a slightly rough, uneven texture.

Process: Technically termed “electrogalvanizing.” Under electrified conditions, zinc ions in a zinc salt solution are reduced and gradually deposited onto the steel component surface, forming a protective layer primarily composed of pure zinc. This is an electrochemical reaction occurring at room temperature.

Coating Characteristics:

Moderate adhesion: A physical coating with significantly lower bonding strength than hot-dip galvanizing; may peel under impact or bending.

Thin coating: Typically 5-30μm thick, offering relatively short corrosion protection.

Appearance: Extremely smooth and uniform surface with a bright, bluish-silver color and high aesthetic appeal.

II.Comparison Overview: Which is Better? It Depends on the Context

| Dimension | Hot-Dip Galvanizing | Cold-Dipped Galvanizing |

| Principles of Preservation | Physical Barrier + Cathodic Protection | Physical Barrier + Anodic Protection |

| Corrosion resistance lifespan | 20+years | 5-15years |

| Coating thickness | >65μm | 5-30μm |

| Adhesion | Extremely strong | Generally |

| Appearance | With zinc flowers, slightly rough, silver-gray | Smooth, uniform, bright silver |

| Cost | high | low |

| Environmental impact | High temperatures consume energy and result in acid mist emissions. | Operates at ambient temperature, offering relatively favourable environmental credentials. |

Key Differences Explained:

Cathodic Protection: This is the core mechanism shared by both methods. Zinc is more chemically active than iron. When the coating is damaged, zinc corrodes before iron, thereby protecting the steel substrate. This means that even at scratched areas, the steel will not rust until the zinc layer is depleted.

Lifespan and Thickness: Corrosion protection longevity is directly proportional to zinc coating thickness. The thicker coating of hot-dip galvanizing provides significantly greater “sacrificial capital” than cold galvanizing, which is the fundamental reason for its extended service life.

III. Industry Application Guide: Precisely Match Your Project

As steel structure builders, how do we recommend the most suitable solutions for our clients?

Outdoor load-bearing structures: Such as exposed crane girders, columns, and roof trusses in factories, or canopy trusses in stadiums. These components endure prolonged exposure to wind, rain, and industrial atmospheric corrosion, with extremely high maintenance and replacement costs. The most durable protection is essential.

Projects with minimal maintenance requirements: such as power transmission towers, highway guardrails, and large pipelines. Hot-dip galvanizing’s “set-and-forget” nature is perfectly suited.

Standard-sized components: H-beams, angle steel, etc., within the capacity of galvanizing tanks.

Large, non-removable components: For the main structures of super-large factories or components that cannot be hot-dip galvanized as a whole due to design constraints, on-site cold galvanizing can be applied.

As a primer in heavy-duty corrosion protection systems: This represents the most classic and scientifically sound application of cold galvanizing (specifically zinc-rich epoxy primers). After sandblasting rust removal, apply a zinc-rich epoxy primer to steel surfaces, followed by an epoxy micaceous iron oxide intermediate coat and a polyurethane topcoat. This approach leverages zinc’s cathodic protection while compensating for the coating’s thinness through intermediate and topcoats, creating a synergistic effect where 1+1>2.

For interior components requiring high surface aesthetics: For decorative steel frames, staircases, and similar elements in commercial complexes, cold galvanizing (or zinc-rich primer) provides a smooth, even surface conducive to applying attractive topcoats.

Repair and maintenance: Damage to the coating on hot-dip galvanized components during transportation or installation can be repaired in situ using cold galvanizing pens or coatings.

As your trusted steel structure partner, we not only deliver high-quality steel components but also provide scientifically sound and cost-effective corrosion protection solutions tailored to your specific project requirements. These solutions encompass hot-dip galvanizing, zinc primer coating, and composite coating systems. Our goal is to ensure every steel structure you invest in stands the test of time.