Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

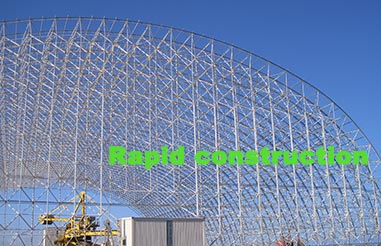

For EPC contractors and construction contractors undertaking factory projects in Africa, efficiency, seamless collaboration and cost control are not mere luxuries—they are critical to success. Steel space frames have become the preferred structural solution precisely because they perfectly address these three imperatives: accelerating construction schedules, enabling seamless coordination and eliminating redundant processes. Unlike conventional building structures that often cause delays or coordination chaos, these frames simplify on-site installation through prefabricated components. This approach can shorten project timelines by over 30% while maintaining cost control—a critical factor when tackling Africa’s unique construction challenges. Their modular design and flexible working methods align seamlessly with EPC workflows, effectively overcoming bottlenecks to ensure projects progress on schedule, stay within budget, and synchronise with team rhythms.

Professional Analysis: Theoretical Foundations The construction advantages of steel spatial frameworks stem from their prefabricated, modular design—approximately 90% of components are pre-fabricated in controlled environments, reducing on-site labour requirements by 40% compared to traditional reinforced concrete structures. This represents a significant breakthrough for African projects, where skilled labour shortages and logistical bottlenecks frequently impede progress. Steel’s combination of lightweight properties and high strength enables rapid assembly without heavy machinery, accelerating construction while reducing fuel and equipment hire costs. For budget management, prefabrication minimises material wastage (typically 5-8% for steel versus 15-20% for concrete) and allows upfront price locking, preventing the budget overruns common in on-site construction.

Thanks to standardised design handover procedures and proactive communication mechanisms, collaboration with the EPC team has become significantly smoother. The steel space frame supplier aligns perfectly with project timelines, with detailed production schedules integrating seamlessly with site preparation and other construction phases. Modular design also facilitates flexible adjustments—enabling changes to project requirements without incurring costly rework or schedule delays. Furthermore, the steel structure’s low-maintenance nature and durability effectively alleviate long-term operational pressures for clients. These advantages significantly enhance the value proposition of your EPC service offering, particularly within Africa’s demanding operational environments.

If you are an EPC contractor or main contractor for African factory projects, these efficiency and collaboration advantages directly address the pain points encountered in your daily operations. Please share this information with your project team to collectively explore how steel space frames can optimise your next construction phase.

Open-ended question: In African plant construction management, which of the following factors is most critical to project success—on-site installation speed, efficient collaboration with structural suppliers, or precise cost control? In what ways have previous structural solutions failed to meet these requirements?