Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

The construction of space frame structures is significantly impacted by on-site conditions and environmental variability, posing substantial risks to safety and quality, particularly for large-scale installations (characterised by extensive spans and considerable height). These projects demand higher safety margins, complex quality control measures, and present considerable installation challenges. Recently, during the construction of Xiahe Port in Xiangyang Port, constraints imposed by the site conditions and tight deadlines precluded the use of large lifting equipment for space frame installation. This significantly increased the complexity of the steel structure works. The adoption of a construction technique combining ‘gable-end initiation with high-altitude loose assembly’ effectively mitigated these difficulties. This approach shortened the construction period, reduced costs, and prevented major safety incidents and quality failures.

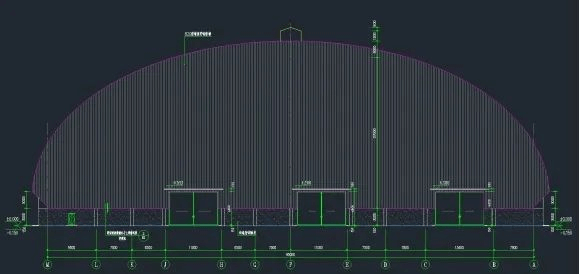

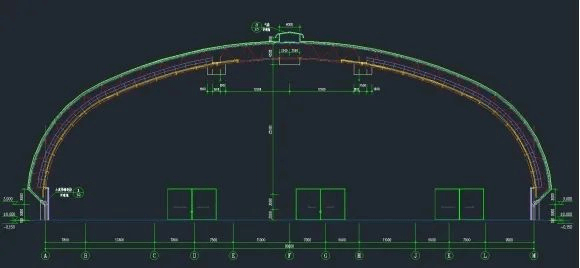

The project’s space frame employs a right-angled tetrahedral grid structure with bolted spherical nodes, forming an elliptical parabolic shell. Structural members utilise thin-walled tubular sections. The span measures 95m (exceeding 60m, qualifying as a hazardous major project), with a longitudinal length of 100m. The entire structure weighs 486 tonnes, employing a lower chord support configuration with a maximum height of 34.20m at its apex. The building incorporates natural ventilation turrets at the roof level, with the roof and end-wall cladding comprising aluminised galvanised profiled steel sheets in an exposed purlin configuration. As illustrated below:

Image 1

Image 2

I.Prior to installation, all components of the space frame—including members and bolted spheres—must be sorted and organised. These should be arranged in order according to specification, size, and serial number to facilitate retrieval during assembly. Subsequently, members and bolted spheres requiring installation should be laid out in the sequence of their installation. Once these preparatory steps are complete, ground assembly of the space frame may commence.

II.Assemble the space frame members into small sub-assemblies on the ground according to the installation sequence, positioning them in their designated construction locations. A small cone assembly constitutes a pre-assembled unit formed on the ground from one spherical node and three to four members. Ground pre-assembly units shall be categorised into lower chord installation quadrangular frames and upper chord installation quadrangular frames.

III.The installation sequence is as follows: bearing sphere → lower chord sphere and lower chord rod → web rod → upper chord sphere and upper chord rod.