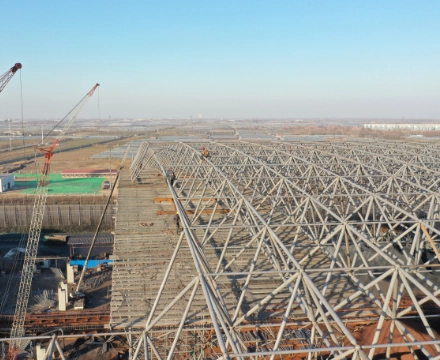

Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

When using bolts in the coal shed space frame, preventing the brittle fracture of steel structure bolts is crucial. To avoid this, identifying the factors causing such fractures is essential. The following points are elements leading to brittle fracture in coal shed space frame bolts:

1. Harm of Loading Rate:

The high loading rate increases the risk of brittle fracture in materials. SAFS Steel Structure Engineering Co., Ltd. has conducted numerous experiments indicating that higher loading rates elevate the risk of brittle fracture, particularly in reduced temperatures. As the deformation rate increases, the tensile strength of the material is likely to rise. This is because the material cannot undergo plastic deformation and load at the same time, reducing the time needed for thermal activation to relieve the texture, raising the brittle transition temperature, and promoting brittle fracture.

The harm of loading rate is more evident when there are voids on the specimen’s surface. Once brittle cracks occur, the crack edge experiences severe local stress, equivalent to a high loading rate load, causing the crack to propagate rapidly and leading to brittle failure of the entire structure.

2. Environmental Conditions for Bolt Application:

The probability of brittle failure of steel structure bolts increases when subjected to significant load effects or operating in relatively low environmental temperatures.

Above 0°C, as the temperature increases, the compressive strength and plasticity modulus of building steel decrease, and generally, the compressive strength decreases, and plastic deformation increases. Between 0°C and 200°C, there is minimal change in the characteristics of building steel.

However, around 250°C, the compressive strength of building steel rebounds, with a significant increase in fy, while plastic deformation and fracture toughness decrease, leading to a “brittle blue” condition. At this point, thermal treatment methods can cause cracks in building steel.

When the temperature reaches 600°C, and E is close to zero, most steel frames completely lack bearing capacity.

Below 0°C, as the temperature decreases, the compressive strength of building steel slightly increases, while plastic deformation and ductility decrease, and brittleness increases. Particularly when the temperature drops to a certain range, the fracture toughness value of building steel drops sharply, resulting in low-temperature brittle fracture. The brittle failure of steel frames in low temperatures is commonly referred to as “low-temperature brittleness,” and the resulting cracks are called “cold cracks.”