Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

I.Introduction to High-Strength Bolts

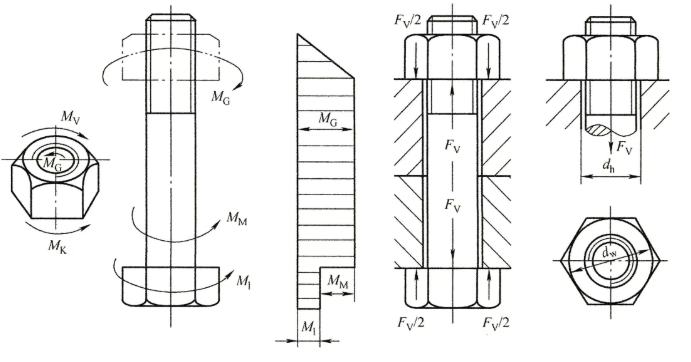

High-strength bolts refer to bolts with performance grades of 8.8 or higher. They are categorized into four grades based on performance: 8.8, 9.8, 10.9, and 12.9. These bolts are typically manufactured from 40Cr steel or other high-quality materials, followed by heat treatment to enhance strength. The mating nuts generally correspond to the same performance grade. The performance grade of a high-strength bolt is usually marked on the hex head or the end of the bolt shank. The strength grade marking consists of two parts separated by a period (.), where the number before the period indicates the nominal tensile strength. For example, the “8” in grade 8.8 represents one-hundredth of the nominal tensile strength of 800 N/mm². The digit following the period in the marking code indicates a yield-to-tensile strength ratio of 0.8, representing the ratio of the nominal yield point or nominal yield strength to the nominal tensile strength. For example, the yield point of a Grade 8.8 product is 640 N/mm².

II.General Methods for Preloading High-Strength Bolts

Ⅰ. Selection of Preload

High-strength bolts typically employ preloading to achieve anti-loosening effects during use. The magnitude of preload must ensure both secure fastening of components and prevent bolt failure. Generally, the working load during actual use is considered to account for approximately 20% of the total load.

High-Strength Bolt Tightening

Tightening is typically performed in 3 to 4 stages.

For a 3-stage process:

– Initial tightening applies 50% of the final torque.

– Second tightening applies full torque.

– Third tightening involves sequential inspection.

For a 4-stage process:

– Initial tightening applies no less than 30% of the final torque. The second tightening applies 70% of the final torque, the third tightening achieves the final preload torque value. The fourth tightening is for inspection, where all bolts are checked and tightened to the final preload torque. To ensure uniform stress distribution across all bolts in the group, both initial and final tightening must follow a specific sequence.

III. Tightening Sequence

For standard joints, tightening should commence from the center of the bolt group and proceed outward sequentially. Work from areas of high joint stiffness toward unconstrained free ends. Follow a radial pattern from the bolt group’s center outward. Prior to initial tightening, mark all bolts for verification. To prevent missed tightening, high-strength bolts installed on the same day must be fully tightened to final torque that day. Final tightening must be performed using dedicated electric torque wrenches. Where manual operation is impractical, hand torque wrenches may be used, provided the final tightening torque meets design specifications.