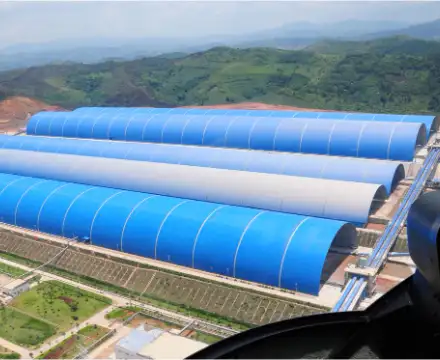

Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

During the process of hoisting, positioning and fixing of the arched roof, its stress state and mode are completely different from the stress state mode after it is in place and fixed.

The spreader of the arched roof is mainly composed of a boom, a wire rope, a fixture and a connecting piece. Lifting equipment generally adopts truck crane. The selection of hoisting equipment is mainly controlled by the size and hoisting height of the hoisting components. When lifting, the stress and deformation of the roof unit panel are very complicated in the transition process from the horizontal placement state to the vertical lifting state. At this time, the stress distribution and deformation of the unit plate are the main factors controlling the success or failure of the hoisting. The stress distribution and deformation of the unit plate are also affected by the hoisting form and the position of the hoisting point.

According to different hoisting point arrangements, there are usually three hoisting forms for arched roof unit panels: two-point hoisting, three-point hoisting and four-point hoisting. Different hoisting forms have their own scope of application for different panel types. Therefore, it is very important to choose the appropriate hoisting form in the actual hoisting. It will be related to the success and safety of the lifting work.

In order to keep the unit plate balanced during the lifting process, the lifting points should be arranged symmetrically along the axis of the arch. Therefore, in the project, the hoisting unit plate group has 3 pairs of V-shaped plates in each group. In this way, the plate can be prevented from tilting due to eccentric gravity during the lifting process, and it is also convenient for on-site construction operations. The lifting point is directly connected to the unit board group by using a special fixture, or it can also be connected to the unit board group by using the auxiliary fixture of strong forceps. When arranging the hoisting point and installing the steel wire suspending rope, make sure that the direction of the resultant force on the hoisting point is vertical to prevent the hoisting rope from generating an excessive horizontal component force at the hoisting point, which will cause the sliding of the hoisting point to affect the hoisting safety of the unit panel group.

Installation and Fixing of curved Roof Unit Panels The key to the installation and fixing of vaulted roof unit panels lies in the first unit panel group. When the first unit panel group is hoisted into place, with the aid of lifting equipment, the theodolite is used to correct the verticality of its installation from different directions perpendicular to each other, and the position of the unit panel vault and the sag height of the roof unit panel are checked with a hanging hammer. is it right or not. During this period, the shaking of the board should be strictly controlled. After the inspection is qualified, the two ends of the arch feet are fixed with self-tapping screws and connecting angle steel, and the lifting equipment can be unhooked. The number of self-tapping screws is determined by calculation, and is evenly distributed along the longitudinal direction, and each unit plate shall not be less than four.

The installation and fixation of other unit board groups can be based on the previous group of unit board groups. After positioning and calibrating, it is connected with the front group of units, and then installed and fixed in sequence. During the installation of the roof unit panel group, it is necessary to maintain the inspection and correction of the verticality of each unit panel group, the position of the curve, the flatness of the ridge line and the parallelism with the longitudinal axis. Find problems and solve them in a timely manner to prevent the gradual accumulation of errors.