Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

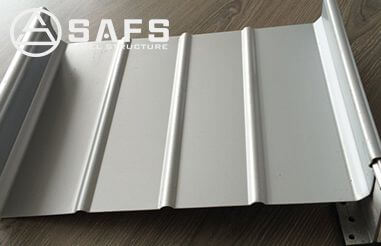

Aluminum-magnesium-manganese panels are currently one of the most popular metal materials in the construction industry. They are widely used in buildings such as sports stadiums, train stations, airports, exhibition halls, and museums.

(1) Lift the aluminum-magnesium-manganese panels to the installation position. Once in place, align the panel ends with the control lines, then press the overlapping edges into the front panel’s overlapping edges. Later, inspect to ensure the overlapping edges are tightly joined.

(2) After adjusting the position of the aluminum-magnesium-manganese panels, use a specialized electric edge grinder to grind the edges. The edge seaming must be continuous and smooth, with no distortion or cracks. The edges to be ground must be clamped within 1 mm of the grinder, which is also critical to the quality of mechanically ground edges.

(3) After completing the installation of the aluminum-magnesium-manganese metal roof system, trim the edges of the aluminum-magnesium-manganese panels to ensure the edges of the aluminum-magnesium-manganese metal roof system are neat and aesthetically pleasing.

(1) Aluminum-magnesium-manganese bracket installation: Aluminum-magnesium-manganese brackets should be fixed vertically to the purlins to ensure balance between brackets. Otherwise, the edge-biting machine may damage the panels or cause leaks or panels being blown away during use. Additionally, when securing the brackets, using high-quality stainless steel nails can prevent electrochemical reactions and ensure that the brackets remain rust-free and secure even after years of use, thereby maintaining the quality of the panels.

(2) Aluminum-magnesium-manganese panel processing: Aluminum-magnesium-manganese panels are directly exposed to air, and material selection considers factors such as wind resistance, stress strength, and corrosion resistance, with strict requirements for panel manufacturing processes. For extra-long panels, when processing on-site, the performance of processing equipment must be considered to ensure that aesthetically pleasing streamlined panels can be easily produced under any circumstances. Additionally, prior to construction, the design of system panel joints should fully consider the actual conditions of the building, including panel edge interlocking, horizontal overlaps, etc. For example, roof surfaces, panel curvature, and panel joints with parapet walls, ensuring the roof system’s exterior finish has excellent waterproofing and insulation performance, with a smooth and flat appearance.

(3) Pre-construction preparation: Before construction, thoroughly inspect the metal roof to ensure it is secure, clean, and free of ice. Address any issues identified prior to construction. Replace damaged fasteners, add fasteners where necessary, and remove ice, dust, and other debris.