Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

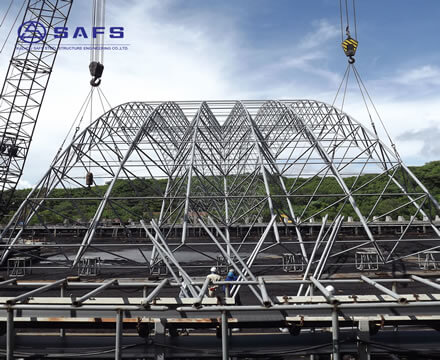

The large-span steel space frame structure of the central circle is assembled on the ground. The small unit is prefabricated and welded from the outside to the inside after the center pole is erected.The reserved part of the center pole shall be hoisted in place and the pole shall be removed before assembly welding. After the welding of the central ring space frame is completed, the connecting rods and balls of the central reserved part are placed on the scaffolding of the steel space frame and lifted together. When lifting, test the deformation first, if there is no deformation, it can be lifted after several test lifting.

The pole-holding wind rope is tied to the third circle of large-span steel space frame structure that has been assembled and welded. Use 1200×1200 lattice steel poles. The total length of the pole is 40m (the length can be extended or shortened), and the maximum hoisting weight is 45t, which is hoisted symmetrically on both sides. After hoisting in place, fix the center ring space frame structure at the design elevation position with guide chains. And align with the corresponding balls in the three circles. Then connect the central part and the third ring of scaffolding for safety protection and then assemble the connecting rods. People need to pay special attention to locking the hoisting rope for double insurance. Because the geometric dimensions and spatial coordinates of the steel space frame structure have been aligned and checked on the ground, only the relative position can be found after the hoisting in place. All assembly welding is completed and then the pole is removed. The detailed calculation can be calculated according to the symmetrical lifting of a single pole with double winches.