Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

In the design of steel trusses, the location of load application is a critical consideration. Many novices or engineers often wonder during the design process: ‘Must loads be applied at the nodes?’ The answer to this question is not absolute; it requires a comprehensive assessment of multiple factors, including the structural form, load type, node construction, and code requirements.

I.Theoretical Analysis: The Nature of Truss Nodes and Load Transfer Mechanisms

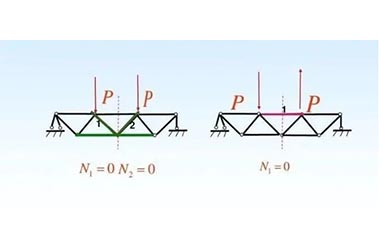

Characteristics of hinged nodes: Under ideal conditions, truss nodes are treated as hinged joints, transmitting only axial forces while resisting bending moments and shear forces. This assumption subjects truss members to purely axial loading, enabling full utilisation of material strength.

Advantages of Load Application at Nodes: When loads act at nodes, all members experience axial forces, avoiding bending deformation and maximising structural efficiency. For instance, in parallel-chord trusses, node loads are uniformly distributed with clearly defined forces.

Node Stiffness and Load Transfer: In practical engineering, truss nodes are not perfectly pinned but possess some stiffness. Should loads act directly on members, the node stiffness induces secondary bending moments, potentially causing localised buckling or stress concentration.

Generation of secondary stresses: For instance, in a trapezoidal truss, applying load midway along the lower chord rather than at the node induces bending deformation in the lower chord, resulting in abnormal forces on adjacent web members.

Applicability of Node Loading: For simply supported or continuous trusses, applying loads at nodes is optimal to avoid secondary stresses.

Special Cases of Member Loading: When loads must act on members (e.g., suspended equipment, piping), stress distribution requires local reinforcement (e.g., stiffeners, gusset plates) or member section modifications.

II.Interpretation of Standards: Load Application Requirements in Design Specifications

Clause 4.1.1: Loads on truss structures shall be applied at joints wherever possible to ensure members are subjected solely to axial forces.

Clause 4.1.2: Where loads cannot be avoided on members, local stability verification shall be performed and structural measures implemented (e.g., stiffeners, welded reinforcement plates).

American AISC Code: Emphasises that node design must account for actual load paths. Where loads act on members, finite element analysis must verify local stresses at nodes.

European Eurocode 3: Requires truss node detailing to accommodate uncertainties in load application locations, with refined modelling undertaken where necessary.

III. Common Misconceptions and Design Recommendations

Misconception 1: All loads must be strictly applied at nodes

Actual situation: In certain circumstances, load application to members is unavoidable (e.g., pipe supports). Safety must then be ensured through local reinforcement and detailed calculations.

Case study: Lighting fixtures required installation on the truss roof of a sports hall, with loads transmitted to the lower chords via supports. The design incorporated additional stiffeners at support locations and verified local stresses in the members.

Misconception 2: Node stiffness has no effect on load transfer

Reality: Node stiffness directly influences secondary stress levels. Excessive node stiffness may induce significant bending deformation in members.

Solution: Employ flexible node designs (e.g., bolted spherical joints) or optimise node construction through finite element analysis.

Misconception 3: Local stability of members can be disregarded when loads act at joints

Actual Situation: Local stability verification remains essential even when loads act at joints. For instance, thin-walled H-section members may experience local buckling under concentrated loads.

Design Considerations: Install transverse stiffeners for compressed members and control slenderness ratios for tensioned members.

IV.Conclusions and Recommendations

Load Application Principles:

Prioritise applying loads at truss nodes to ensure members are subjected to axial forces.

Where loads must act on members, safety shall be verified through local reinforcement, structural optimisation, or finite element analysis.

Design Recommendations:

Prioritise Standards: Strictly adhere to the Steel Structure Design Code and industry regulations to ensure rational load transfer pathways.

Refined Modelling: Employ finite element analysis for complex scenarios, accounting for factors such as node stiffness and material non-linearity.

Constructive Measures: Install stiffeners and weld-on reinforcement plates to enhance local bearing capacity.

The calculations must correspond to the actual construction: when trusses are calculated as compression members, loads may be distributed to individual bays; when calculated as axial members, both calculations and construction drawings must ensure loads are transmitted solely to truss nodes.

With advances in structural analysis software and digital design, truss load distribution can be achieved with greater precision, while node design flexibility and reliability will be further enhanced.