Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

Space frame is a spatial structure composed of multiple poles, connected by nodes in a certain space frame form. Then, how are the Space frame rods processed, operated, and controlled in the actual production process?

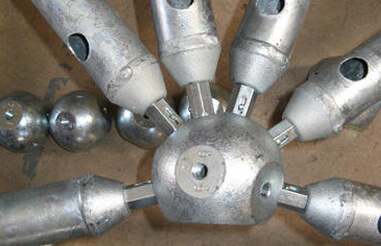

Nowadays, we can see many high-rise buildings in the streets and alleys of the city, such as some large convention and exhibition centers. In fact, these buildings cannot be without accessories such as space frame screws. At present, the bolt ball is an indispensable thing in construction, and the bolt ball is widely used, but do you know its manufacturing process?

In fact, in the process of making bolt balls, we must install them in order. According to the form of the space frame, the type of support, and the force of the structure, we still need to pay attention when installing the bolt balls. In fact, the bolted ball space frame has many characteristics, mainly a three-dimensional structure, so the structure of the bolted ball space frame is very stable, and the overall weight is relatively light. These are mainly hollow ball joints, bolted ball joints and bolted connection nets.

For example, it is widely used in some difficult places and in some large steel structure buildings. However, in space frame engineering, the part that is prone to error accumulation is the processing of rods. The final length of the steel pipe depends on the material size of the steel pipe, the thickness of the sealing plate or cone of the steel pipe, and the thickness of the weld seam, and the thickness of the steel pipe depends on the design value of the length of the steel pipe. Therefore, in the specific welding process, the weld size of the steel pipe should be controlled according to the requirements of different weldments and the thickness of the welds. This requires that the rods of the same specification be made “sample bars” first to achieve correction welding the purpose of sewing size. The anti-rust rod should ensure that it reaches the anti-rust level required by the design. Pipes with heavy rust stains and pipes that have been stored for too long should be thrown twice and visually inspected to see if they have reached the anti-rust level of the anti-rust rod. The anti-rust level must be ensured to ensure the weather resistance of the anti-rust rod. Sex. The coating is the last process to form the grid pole. The spray paint should be even, not through the bottom, and not sag. After the first painting is completed, be sure to paint a second time.