Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

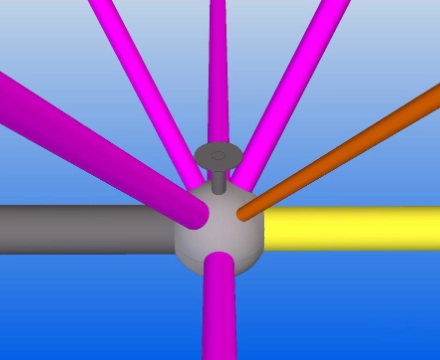

For a cross-node plate with bidirectional forces, only the effect of the force in its own plane needs to be considered in the design, and the effect of the force in the other direction can be ignored. When there is no cover plate, the cross-node plate can be designed according to the flat section assumption. When there is a cover plate, the cross node plate and the cover plate should be considered to work together. The magnitude of the force between them is related to the ratio of their tensile and compressive stiffness. The thickness of node plate can be generally selected with reference to the selection method of plane truss node plate thickness, which can be taken with reference to the maximum internal force of space frame. For the middle node, smaller thickness can be selected; for the support node, larger thickness can be selected. Then according to the space frame span, working condition and node structure and other factors to consider the decision. The node plate is too thin and prone to welding bite meat and larger welding deformation, and also prone to lateral buckling of the node.

In the welded steel plate node, the middle vertical weld of the cross node plate is the key weld of the node, which has to withstand the stresses transmitted from the node plate in both directions, and the stress situation is relatively complicated. Test and analysis results show that, for the bevel weld middle vertical weld, when the two directions of the node plate is the same tensile or compressive, the positive stress in the positive section is basically proportional to the positive stress direction lock applied external force, while the positive section of the shear stress is small, in line with the theoretical stress state of the bi-directional stress. However, when the two directions of the node plate has always been subjected to tension, has always been subjected to pressure, that is, the sign of the stress transmitted from the node plate is different at the same time, regardless of its absolute value is equal or not, the weld will produce a larger shear stress. When the two-way applied tension and pressure values are equal, the maximum shear stress value is almost equal to the stress value from the node plate. Since the shear strength of the butt weld is lower than the tensile and compressive strength, the shear stress will be the controlling factor when designing the intermediate vertical weld of a cross-node plate that is always under tension and always under pressure.

In the design of the bevel weld cross node plate of the middle vertical weld, should be based on the two directions of the node plate from the stress sign is the same and differentiated. When the two directions of stress is the same, can be approximated by the node plate to pass the maximum stress for weld strength calculation, calculation can be used to press the weld, compressive strength design value. When the two directions of the node plate stress sign is different at the same time, in addition to the above method of tensile and compressive strength check, should also be calculated its shear strength, shear stress value can be approximated according to the two directions of the node plate to pass the absolute maximum value of stress multiplied by the coefficient of p, to obtain the following formula, that is: the bar and the cross node plate and the cover plate of the connection between the weld seam, generally using fillet weld in the welded steel plate nodes without cover plate, the Generally use two sides of the side welding, can also be used three sides of the circumferential welding or L-type circumferential welding (the strength of the connection can be based on the shear of the corner weld). When the fillet weld can only be set at the tip of the angle steel limb out, limb back can not be welded, at this time can be this a Yong groove weld and fillet weld combination of connection, that is, at the tip of the angle steel limb fillet weld based on the angle steel connection with a single steel plate at the angle to open the elliptical groove holes and along the perimeter of the groove holes imposed fillet weld in order to increase the connection of the load carrying capacity. Its basic damage characteristics for the effective shear along the weld and damage, bearing capacity can be calculated according to the general fillet weld.