Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

Today, I will take you to understand the complete construction plan and acceptance specifications of the spherical space frame steel structure in detail. Please indicate the source of the article for reprinting, and I hope it will be helpful to you.

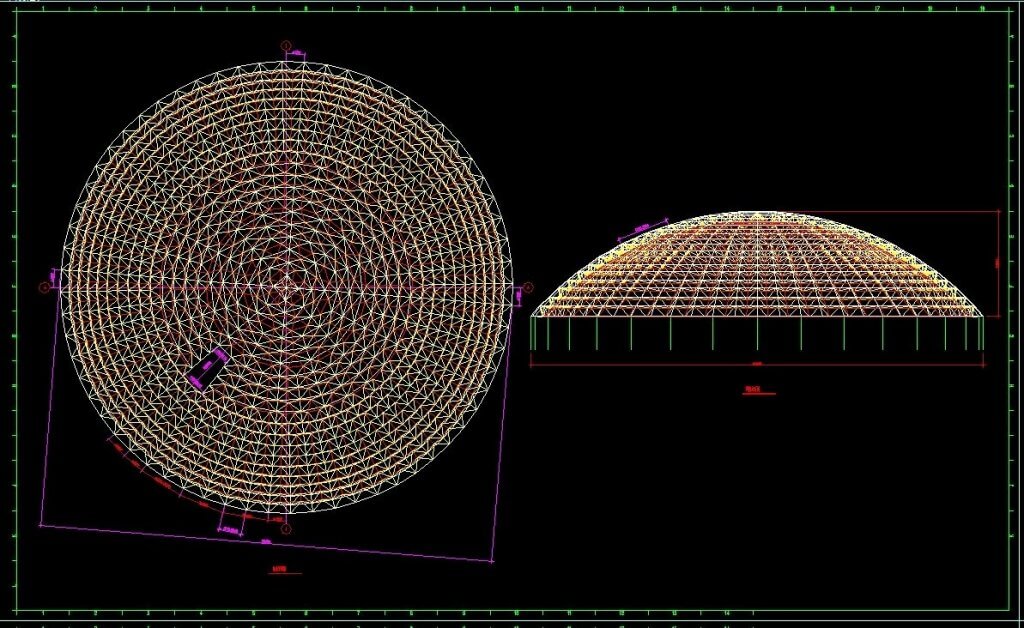

The space frame adopts the method of placing square pyramid, adopts bolt ball joints, adopts general seamless steel pipes, and adopts level rubber bearings with electric welding on both sides.

The space frame processing adopts a polycarbonate flat roof and a single-sided internal drainage pipe method with small vertical poles to find the slope. The thickness of the drainage ditch is 6 mm.

The construction of the project is divided into two phases: manufacturing and on-site construction and installation. The scaffolding required for the project should be erected on the construction site when the contract takes effect until the installation is in the factory, and the installation team should prepare for construction.

The space frame manufacturer must prepare in advance for the construction team’s construction water and electricity consumption, implement the problem of raw material hoisting accumulation, deal with the life problems of the construction team, and coordinate with the bidding party to make a good plan in the work.

① Preparation work for construction work surface

In the construction and setting-off work:

Scaffolding inspection:

Inspect the scaffolding, eliminate the columns that highlight the work surface hazards to the construction, and make it consider the erection regulations.

② The construction workers are divided into two technical work types: installation and electric welders. Under the unified leadership of the team leader, they work together to ensure the efficient completion of daily construction tasks.

The raw materials of the company are all obtained from dealers with high creditworthiness and stable and reliable quality. After entering the factory, in addition to the requirement that the original quality inspection sheet must be provided, sampling and review shall be carried out to control the quality of the raw materials.

The original parts of the frame are all packaged, and the components are packaged in bundles. The finished bolt ball is packed in a packaging bag and then put into an iron basket. All parts are packaged and palletized, and the labels are affixed. Pay attention to storage during transportation to avoid evaporation and damage. The original manufacturer of the frame spare parts shall show the certificate of conformity.

After the technicians and quality supervisors enter the site, they carry out center-line inspection and flatness inspection on the supporting surface of the civil engineering, and strictly do the recording of each level of data information.

During the entire installation process, the inspector should immediately check the installation position of each net frame component and each ball, whether the net frame installation perspective is appropriate, and if any problems are found, change it anytime and anywhere. In addition, check whether the high-strength bolts are tight and timely. Pay attention to the deformation, that is, the flatness and flatness. After each column spacing is installed, the center-line should be checked immediately, and the problem should be adjusted immediately, so that the cause of the deviation will not accumulate beyond the construction scope regulations, and ensure that the installation of a span is qualified. For the first step, for the electric welding of the rubber bearing, it is stipulated to pay attention to the paving and firmness of the connecting plate and the preform, and the welding must ensure the compressive strength.

In the whole process of quality inspection, the quality inspection staff must do their responsibilities and strictly manage to ensure the construction quality of the project. After the quality inspection staff finds the problem, they must deal with it carefully and do a good job in the re-examination after the solution. The quality inspection must be done well for records and quality summary.

After the space frame manufacturer is installed, the quality inspection personnel of the enterprise will carry out a comprehensive inspection of all engineering projects, compare the construction standards and technical specifications, do a good job in the self-inspection, sort out the construction materials, make records, summarize the construction work experience, and help the bidding party, design plan, project supervision, quality inspection and other units are doing a good job in project acceptance.

The construction quality management method should center around the entire process of all frame construction. It is the core work of all-round quality management. The technical guidance of technical personnel and the inspection and supervision of quality inspectors should accompany the smooth construction of the space frame. Carry out a span, add a temporary support point column, carry out a span, inspect a span, and deal with the problem immediately. At the end of the work of the day, the team leader must do a work report and construction essays and prepare for the assignment of the next work.

All construction workers must learn the relevant requirements of safe construction, recognize the strategic policy of “safety is more than everything, prevent trouble before they happen”, and have a sufficient understanding of the high-altitude operations of the space frame project, and they must not be negligent. The project manager and team leader must be responsible for safety to avoid safety accidents.

For more information, click me to Get Free Project Quote.