Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

The strip-shaped closed coal bunker has the advantages of sealing, environmental protection, and coal storage in separate piles, which not only ensures that coal combustion and operations are not affected by climatic conditions, but also avoids coal dust spilling and polluting the environment. With the improvement of environmental protection requirements, there will be more and more applications of strip-shaped closed coal bunkers in the water transportation industry. According to the characteristics of different projects and site conditions, there are similar but different construction techniques.

According to the requirements of environmental protection, the first-phase project of Guangdong Huizhou Port Coal Wharf adopts a large strip-shaped closed coal bunker to store coal, and the upper part of the coal bunker is a space frame + purlin + high-strength pressed steel plate structure. Combined with the characteristics of the project and site conditions, in order to speed up the installation efficiency and improve the installation accuracy, the space frame adopts a combination of the overall jacking process, the strip and block top hanging process and the high-altitude bulk process for installation. During the installation process, the superstructure of the reticulated shell is fully, systematically and automatically monitored for the whole process, and the construction of the reticulated shell is measured simultaneously to ensure the quality and safety of the installation. The successful implementation of this project can provide examples and experience for similar projects of water transportation engineering.

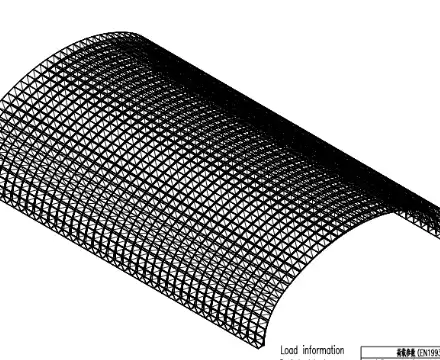

Two strip-shaped closed coal bunkers store coal: a single block is 500m long, 118m wide, about 43.7m high, about 57,500 square meters, and about 74,500 square meters, of which the straight section is 441m long and the end The radius of the hemispherical shell is 59m, the radius of the large circle of the three-centered circle is about 71.4m, and the radius of the small circle is about 36m.

The foundation of the coal bunker is the maintenance structure of bored piles + anchors + concrete columns, coal retaining walls and brick walls, and the elevation of the bearing surface is 4.3 m. The upper part of the coal bunker is a space frame + purlin + high-strength pressure steel plate structure. The space frame adopts a positive-placed quadrangular pyramid double-layer three-centre cylindrical arc reticulated shell structure. The grid size is 4m long, 4m wide, and 3.5m thick. Point support, the node types are bolt ball (upper part of space frame), welding ball (lower part of space frame), intersecting node, the primary and secondary purlins are arranged in double layers, and the primary purlin is high-frequency welded H-beam H200mm×1500mm×3.2mm × 6mm, the secondary purlin is XZ1600mm × 60mm × 20mm × 2.2mm; the total steel space frame is about 7000t, and the primary and secondary purlins exceed 1400t.

The space frame structure is widely used in the field of large-scale infrastructure construction in my country, and is suitable for industrial and civil buildings with various supporting conditions and various plane shapes and spans, such as stadiums, theaters, exhibition halls, waiting halls, hangars, two-way large columns from the workshop, etc. The space frame structure has its unique advantages: the span and height of the structure can be larger, and the rigidity of the structure space is large, the integrity and stability are good, and it has good seismic performance, and a beautiful building can be designed on the premise of satisfying the use. Modeling; shortcomings: the number of structural rods is large, and the production and installation are more complicated than the plane structure.

According to “Technical Regulations for Spatial Grid Structure”, the installation method of spatial grid structure should be comprehensively determined according to the type, force and structural characteristics of the structure, on the premise of ensuring quality and safety, in combination with schedule, economy and technical conditions of the construction site. , there are 7 main types:

Combined with the characteristics of the project and site conditions, in order to speed up the installation efficiency and improve the installation accuracy, the coal bunker space frame of the project adopts a combination of the overall jacking process, the strip and block top hanging process and the high-altitude bulk process for installation, and the construction is divided according to the expansion joints of the space frame. In the area, the space frame of the straight section is installed by the overall jacking process and the top hanging process of strips and blocks, and the end hemispherical shell and the space frame of the connecting section are installed by the high-altitude bulk process altitude bulk process.