Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

More and more people asking which is better for steel structure space frame roof panels?

Maybe the answer you get on Google should be like this: most of them use color steel plate roofs, and now most of them adopt Al-Mg-Mn roofing panel. Generally, color steel plate roofs are enough for factory buildings.

What kinds of materials are there for steel structure space frame roof panels? What’s the difference between of them? SAFS Steel Structure Company will give a detail analyst here.

Firstly we need to understand that the steel structure space frame roof is a spatial network structure composed of rods along a certain curvature or plane. It is suitable for large-span buildings such as gymnasiums, theaters, swimming pools, power plant coal storage sheds, factory warehouses, etc., and what kind of roofing material to use needs to consider many factors such as beauty, durability, waterproof, service life and so on. Of course, the cost is also an essential consideration.

The following are the five commonly used materials for steel structure grid roof panels, and the differences between them:

Roof panel—single sheet panel (color steel plate, Al-Mg-Mn plate, aluminum veneer, aluminum-plastic panel).

Single-layer color steel plate: The profiled roof panel is roll-formed with a color steel plate. This kind of roof panel has poor thermal insulation performance.

The common thickness of color steel plate is 0.376mm, 0.4mm, 0.426mm, 0.476mm, 0.5mm, 0.6mm, 0.8mm

The calculation method of the color-coated roll: the number of meters = 1000KG/thickness/7.85, the price per square = the unit price per meter/plate type.

The difference between the angle chi-shaped color steel plate and the ordinary profiled color steel plate: the angle chi color steel plate is specially used for the roof, and the corrugated height is higher than that of the traditional pressure-shaped color steel plate. The traditional color steel plate is installed with self-tapping screws, and the angle chi color steel plate is fixed and installed with the angle chi bracket.

On-site composite board – glass insulation cotton is laid on the construction site, and the roof panel can be processed on-site according to the length requirements. This kind of roof panel has good thermal insulation performance, the whole roof can be achieved without overlapping, and the transportation is convenient.

The common practice is: color steel bottom plate + glass wool on-site composite + color steel roof plate, generally have purlin exposed type and purlin hidden type two ways.

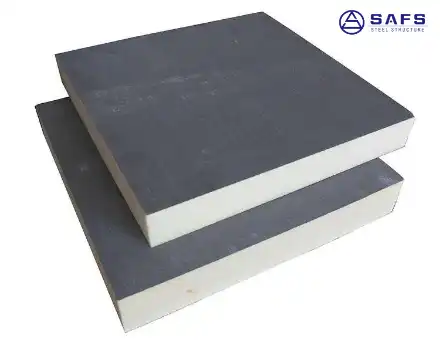

Sandwich roofing panel is made up of two layers of waterproof color coating steel plate or other metal as panel, intermediate injection composite sandwich board material, commonly used materials for sandwich polystyrene, polyurethane and rock wool, the roof plate heat preservation performance is good, but due to the factory processing, when the length exceeds a certain request, it is difficult to transport.

Rock wool sandwich panel is a new type of fireproof panel with the strongest fire resistance among the color steel plate series. It is made of natural rock, blast furnace iron slag, etc., which are melted into filaments at high temperature, and then solidified and formed.

Rock wool belongs to inorganic heat insulation material, is iron slag as the main raw material, after melting, with high pressure steam spray cooling, with light weight, small thermal conductivity, good elasticity, non-combustion, no decay, no rot, chemical stability, but also has excellent sound insulation performance.

Rock wool sandwich panels are widely used in various fire and sound insulation places in addition to the general active structures that play the role of thermal insulation.

Sandwich panel (there are six types according to the core material)

① polystyrene sandwich panel (EPS sandwich panel) ② extruded polystyrene sandwich panel (XPS sandwich panel), ③ rigid polyurethane sandwich panel (PU sandwich panel), ④ three polyester sandwich panel ( PIR sandwich panel), ⑤phenolic sandwich panel (PF sandwich panel), ⑥rock wool sandwich panel (RW sandwich panel), core thickness 50-300mm, plate type (commonly used 950.1000.1150.1200)

Al-Mg-Mn plate is a material made of aluminum alloy as the main base material. The advantages and disadvantages of this plate are also quite obvious:

The thickness of the Al-Mg-Mn plate is generally 0.7-0.9 mm. From the above content, it can be seen that, in a simple analogy, the Al-Mg-Mn plate is a color steel plate with different materials.

The use effect is obviously better than that of color steel plate, but there will be similar problems with color steel plate in long-term use.

Steel frame light mesh plate is a kind of foamed cement composite plate, which is composed of light steel frame, cold drawn steel wire mesh, inorganic modified cement perlite composite core material (proprietary technology), inorganic composite anti-permeability and wear-resistant coating (proprietary technology).

Steel skeleton light space, can solve the traditional sheet (e.g., color steel sheet) cold frost condensation phenomenon, and compared with the traditional plank (such as concrete slab) greatly reduce the construction difficulty, change and reduce the working procedure of the waterproof layer, can be integrated steel structure itself, can well realize network frame of the roof waterproof, thermal insulation, wind load and snow load, and other functions.

The steel structure skeleton and the steel skeleton light board (including floor slab, wall slab and roof board) are made into an integrated load-bearing board, which can be made into a multi-storey structure prefabricated building; the steel frame is equipped with external hanging and internal wall panels to realize high-rise or super high-rise prefabricated buildings. Equipped with detachable partition wall panels, refractory decorative panels, etc., so that all complex projects can be processed in the factory, and assembled quickly on site, improving building performance and reducing overall costs.

The steel frame light space frame plate has fast installation speed and few construction links, which greatly shortens the construction period;

The shape and specifications of the steel frame light space frame plate can be customized according to customer requirements, which can meet the requirements of opening holes and hanging objects;

The steel frame light space frame plate provides a convenient and reasonable solution for the supporting construction of lighting skylights, fan equipment, lightning protection system and secondary decoration. At the same time, for long-term use, the cost is lower, and no special maintenance is required. Partial damage can be directly repaired on site.

If necessary, the single board can be replaced without affecting the overall structure.

SAFS Steel Structure Engineering Co., Ltd. has a wealth experience in the space frame structure industry. Today, we mainly introduce 5 kinds of roof panel materials, and we will analyze its accessories later, such as: bolt balls, welding balls, high-strength bolts, steel pipes, cones, let more friends understand it deeply, of course, if you have any questions, feel free to leave the message, we will be glad to help.

The following video is the installation method of steel structure space frame roofing.